FAQ

Frequency Asked Questions. Please ask us anything you are wondering!Is there any precautions before installation?

– Please avoid the external shocks, rapid beat and extreme tightener.

– Please keep it at room temperature storage and avoid direct sunlight.

– If the wire is wound as reel type (without spool), please release it from the inside. You can use it without loss.

– You must avoid the pressurized conditions to the wire.

ex) When you install it in the place pressed by a load or something, it may be damaged due to the weight.

Please install the cable surface avoiding pressure or force.

– If the wire installs in high frequency environment, you should inform us in advance.

We need to check the surroundings’ conditions.

Can the users replace only 'Heat Detector Wire' in existing installed systems?

Yes, they can. most of customers have used it and want to replace only ‘Heat Detector Wire’ because the fire system excluding the wire is OK. Many of them have selected YDK HDW and saved their maintenance costs. YDK HDW is much cheaper and high-end quality compared to German-made, Japanese-made & USA-made.

What application is YDK Heat Detector Wire for ?

It is used for following places.

Archive, Bridges, Cable Trays, Cable spreading spaces, Cooling towers, Cooler storage, Conveyor belts, Elevator shafts, Engine Bays, Generators, In Cabinet, In-Rack Freezer, Motors, Machinery, Mini storage facilities, Paint booths, Parking decks, Pumps, Switchgear, Terminal Rooms, Tunnels, Warehouse storage, Tire factories

Is there a minimum order size?

Yes, it is more than 10,000m per shipment. If we have stock, we can supply you small volume.

How many kinds of product class regarding temperature do YDK have?

| Celsius(℃) | Fahrenheit(℉) |

|---|---|

| 80℃ | 176℉ |

| 90℃ | 194℉ |

| 100℃ | 212℉ |

| 110℃ | 230℉ |

| 120℃ | 248℉ |

| 130℃ | 266℉ |

How does it find the disconnected point where the heat occurs?

We provide you ‘Ω/km’. If the specific part gets heat, the two wires’ insulation is melting rapidly which means occurs shorts. From both ends of the system, you can see the disconnection point by reduced resistance value through the inversion calculation based on initial default value.

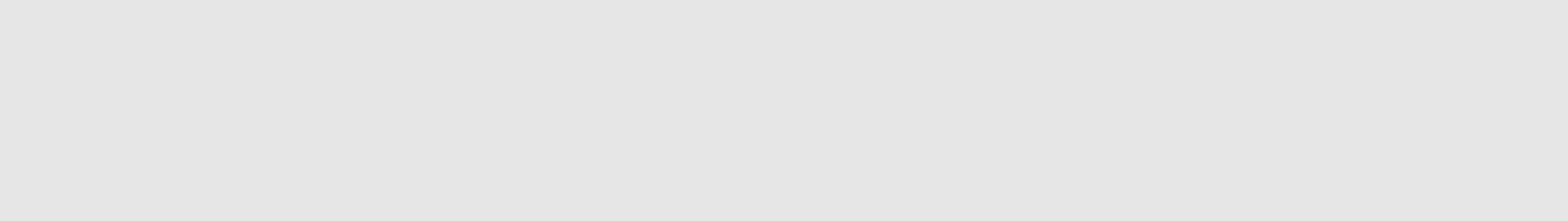

How is it installed with cable?

Does it withstand high voltage?

If you request us, we conduct high voltage test pursuant to 60092-350 IEC:2008(E) as following.

5.2.3.4 Voltage test on sheath

The test shall be made on sheathed cable where there is a metallic layer under the sheath. The whole length of the completed cable as delivered shall be spark-tested (see 5.2.3.7).

5.2.3.5 Test voltage

Unless otherwise stated in the applicable product standard for the cable, the values of the test voltage for the standard rated voltages are given Table 2.

Table 2 – Routine teat voltage

| Rated voltage of cable(kV) | Alternating current (AC, kV, test voltage for 5 min.) |

Direct current (DC, kV, test voltage for 5 min.) |

|---|---|---|

| 0.15/0.25 | 1.5 | 3.6 |

| 0.6/1 | 3.5 | 8.4 |

| 1.8/3 | 6.5 | 15.6 |

| 3.6/6 | 12.5 | – |

| 6/10 | 21 | – |

| 8.7/15 | 30.5 | – |

| 12/20 | 42 | – |

| 18/30 | 63 | – |

Note: The value for enhanced insulation thickness are given in the product standard.

DC testing is not recommended for cables with rated voltages > 1.8/3Kv.